PUMPS

A collection of hand operated diver’s air pumps. These pumps were meant to provide air to divers in warm shallow water.

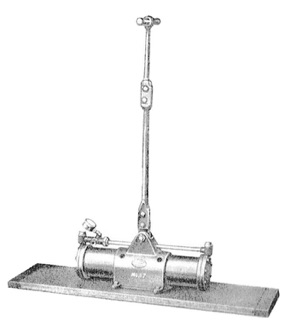

Morse #15 shallow water divers air pump

Hand Operated Air Pumps

The Diving Machines’ collection of mid-1900's hand-operated American shallow water hard hat diver's pumps include the Morse #15, Miller Dunn and Diving Equipment & Supply Co. systems. These heavy all brass pumps have two reciprocating cylinders mounted astride a vertical or horizontal support with pivoting rocker arms. A steel handle used at the top of the rocker is pushed back and forth actuating the leather ringed piston plungers, forcing air up through a non-return check valve and on to the diver's helmet.

The New York-made Snead two-stage pump provided a higher pressure than most equal cylinder-sized lever pumps. Air from the larger cylinder was compressed down into a smaller cylinder providing even a greater out pressure for higher pressure applications.

Single-cylinder air pump with volume tank.

Cleveland and Faucet Co. hand air pump, Cleveland Ohio, USA.

Early US Navy modified hand operated shallow water divers air pump

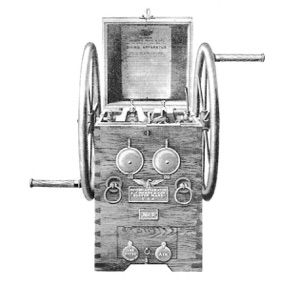

Rotary Pumps

Morse Diving two-cylinder rotary diver’s hand-operated air supply pumps.

Morse Diving single-cylinder rotary diver’s hand-operated air supply pump.

.

Restoration;

The Siebe Gorman Project

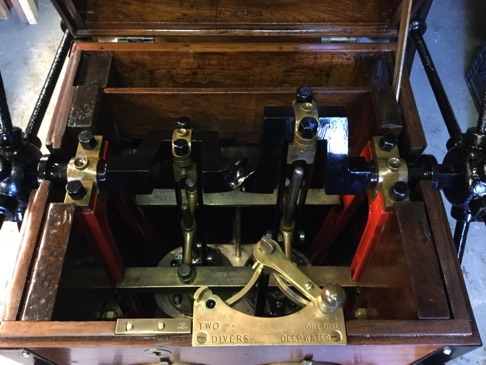

This year I had the opportunity to purchase a Siebe Gorman Admiralty 3 cylinder 2 diver rotary air pump from Commercial diver Mr James S McFarlane from Bridgewater Nova Scotia Canada.

The Siebe Gorman pump in it’s original condition as you can see from the images it was in need of a good overhaul.

The first step was the tear down removing the pump cylinder base from the wooden box.

Break down of the cylinder plunger arms and removal of the leather piston cups from the cylinder body.

Siebe Gorman uses two leather piston cups on each plunder one opposite each other to compress air on both the down and upward stroke. Both the lower base and cylinder heads contain two sets of valves each to assist this process.

The before and after pictures of the cylinders that were slightly scored and needed a minor honing before reassembly.

These 4 pictures show the upper and lower valve assembly

A complete break down image of the cylinder piston plunger

The before and after pictures of the plunder cam shaft. After inspection of the shaft we noticed a slight warp on the ends where the wheels sit and the lobes were the plunger arm attaches was slightly pitted and needed to be machine turned. This was a little tricky for the machinist but he was able bring it back to spec .

The original teak box was in really bad shape and took made most of the restoration hours, patients is the key. Siebe Gorman used Shelac on all there pumps and finding the correct shade crystals took some time.

The teak box after restoration the goal was to make it functional with a aged look, there were plenty of crack that needed repair through out.

Before and after restoration pictures of the The Siebe Gorman copper water cistern that surrounds the cylinders, this is used to cool the cylinders down during operation when the leathers become hot and secondly provides cooler air down to the diver. when the pump has been sitting for some time in storage the cylinder oil may become a little stiff at this point you would pour hot water down the cistern to warm and loosen up the cylinders leathers for a smoother operation.

We had to produce new leather cups for this pump as the originals were rotted away and of no use. The Siebe Gorman pump uses a special 4”od cup with a 1” down wall this is necessary because the leather brass retaining disc that fits into the leathers that contain a set of internal springs that push outward on the leather cup from the inside against the cylinder wall for added pressure and better sealing.

The completed project above total time spent about 4 months and $800. The pump is like new pumping plenty of air for one or two divers. I hope to use this pump in our 2017 summer diving season.